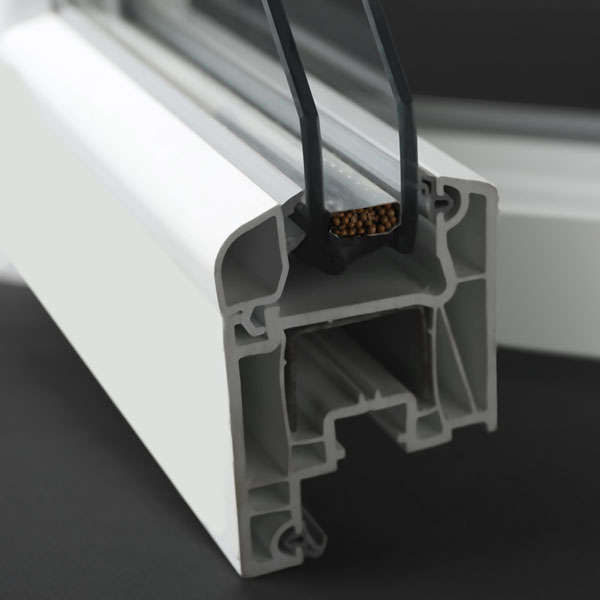

תרכובות קשיחות

בית > Hoses > תרכובות PVC > תרכובות קשיחות

מידות

630 Natural

Application: rigid profiles| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.56-1.62 |

| Hardness | ASTM D 2240 | SHORE D | 72-80 |

| Tensile Strength | ASTM D 638 | n/mm2 | >20 |

| Elongation | ASTM D 638 | % | >40 |

| Thermal Stability | 200°C | minutes | >60 |

632 WT

Application: rigid hoses & Profiles| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.45-1.51 |

| Hardness | ASTM D 2240 | SHORE D | 79-85 |

| Tensile Strength | ASTM D 638 | n/mm2 | >30 |

| Elongation | ASTM D 638 | % | >100 |

| Thermal Stability | 200°C | minutes | >60 |

633 WT

Application: Rigid profiles for construction| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.49-1.51 |

| Hardness | ASTM D 2240 | SHORE D | 70-81 |

| Tensile Strength | ASTM D 638 | n/mm2 | >30 |

| Elongation | ASTM D 638 | % | >20 |

| Thermal Stability | 200°C | minutes | 60 |

634 Natural

Application: lintels and rigid profiles| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.50-1.60 |

| Hardness | ASTM D 2240 | SHORE D | 70-78 |

| Tensile Strength | ASTM D 638 | n/mm2 | >10 |

| Elongation | ASTM D 638 | % | >20 |

| Thermal Stability | 200°C | minutes | >60 |

502 BTL

Application: Transparent low impact for blowing and extrusion| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.32-1.36 |

| Hardness | ASTM D 2240 | SHORE D | 68-78 |

| Tensile Strength | ASTM D 638 | n/mm2 | > 40 |

| Elongation | ASTM D 638 | % | 100.00 |

| Thermal Stability | 200°C | minutes | 60 |

525 BTL

Application: Transparent medium impact for blowing and extrusion| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.31-1.35 |

| Hardness | ASTM D 2240 | SHORE D | 70-78 |

| Tensile Strength | ASTM D 638 | n/mm2 | > 40 |

| Elongation | ASTM D 638 | % | >100 |

| Thermal Stability | 200°C | minutes | 60 |

506 BTL

Application: Transparent high impact for blowing & extrusion| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.30-1.35 |

| Hardness | ASTM D 2240 | SHORE D | 65-75 |

| Tensile Strength | ASTM D 638 | n/mm2 | > 30 |

| Elongation | ASTM D 638 | % | > 30 |

| Thermal Stability | 200°C | minutes | 60 |

507 BTL

Application: Transparent medium impact for vacuum forming| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.32-1.36 |

| Hardness | ASTM D 2240 | SHORE D | 74-78 |

| Tensile Strength | ASTM D 638 | n/mm2 | > 35 |

| Elongation | ASTM D 638 | % | > 100 |

| Thermal Stability | 200°C | minutes | > 60 |

525 Nartural

Application: Rigid profile for extrusion| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.36-1.44 |

| Hardness | ASTM D 2240 | SHORE D | 72-80 |

| Tensile Strength | ASTM D 638 | n/mm2 | > 35 |

| Elongation | ASTM D 638 | % | > 100 |

| Thermal Stability | 200°C | minutes | > 60 |

528 Natural / Black

Application: Rigid Injection molding| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.38-1.48 |

| Hardness | ASTM D 2240 | SHORE D | 69-75 |

| Tensile Strength | ASTM D 638 | n/mm2 | > 20 |

| Elongation | ASTM D 638 | % | > 20 |

| Thermal Stability | 200°C | minutes | > 60 |

582 Natural/ white

Application: Granulated base for foaming extrusion| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.42-1.50 |

| Hardness | ASTM D 2240 | SHORE D | 71-77 |

| Tensile Strength | ASTM D 638 | n/mm2 | > 30 |

| Elongation | ASTM D 638 | % | > 10 |

| Thermal Stability | 200°C | minutes | > 60 |

624 WT

High impact UV stabilizeApplications: shades and profiles

| Properties | Test Method | Units | Standard |

|---|---|---|---|

| Density | ASTM D792 | gr/cm3 | 1.50-1.60 |

| Hardness | ASTM D 2240 | SHORE D | 67-79 |

| Tensile Strength | ASTM D 638 | n/mm2 | > 20 |

| Elongation | ASTM D 638 | % | > 50 |

| Thermal Stability | 180°C | minutes | > 60 |