Blog

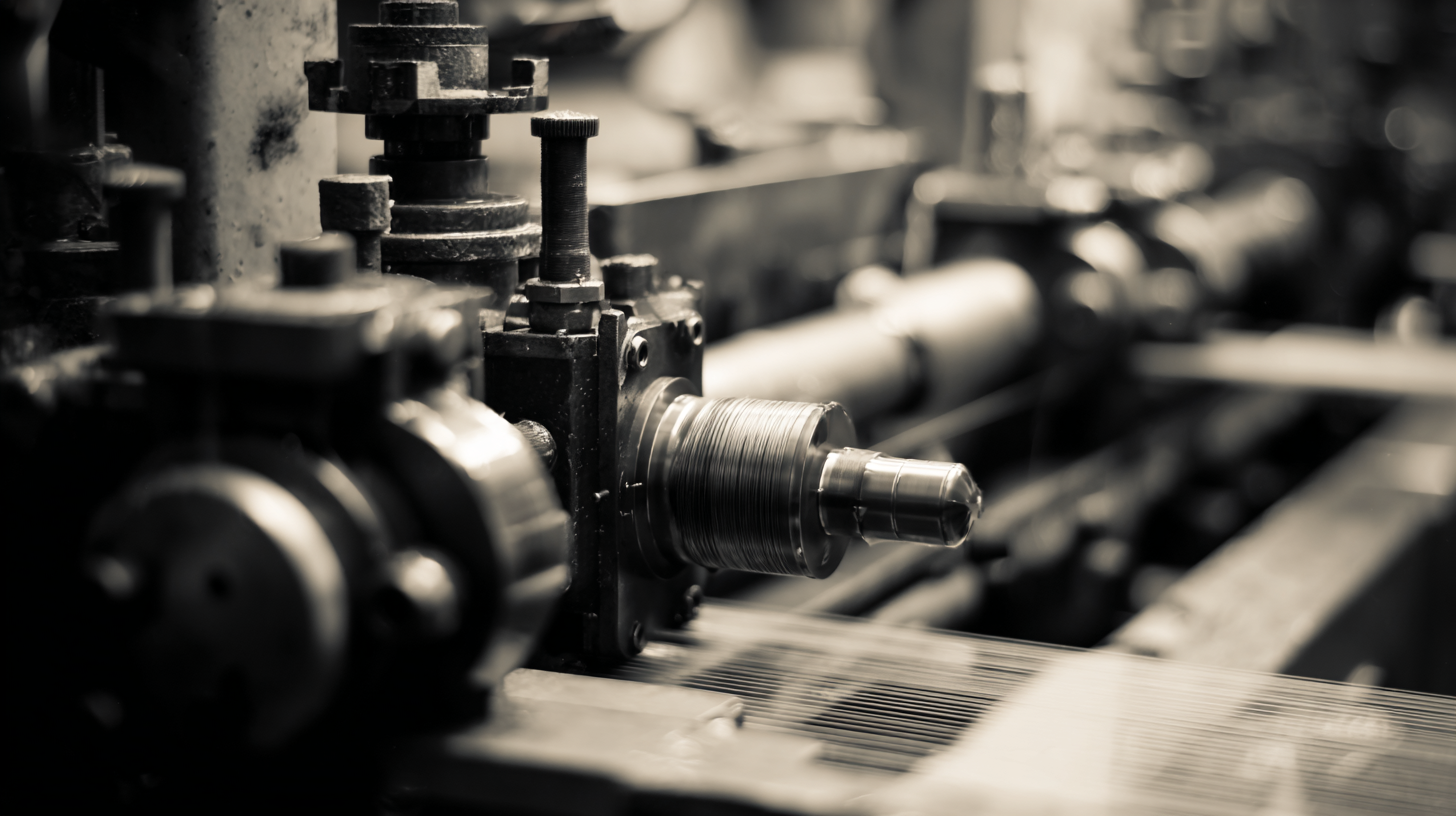

Unlocking the Secrets of Hose Manufacturing: How Quality Materials Enhance Performance and Durability

In the competitive landscape of hose manufacturing, the selection of quality materials stands at the forefront of ensuring performance and durability. The Global Hose Market, which is projected to reach USD 13 billion by 2026, emphasizes the growing importance of material quality in the production process. As hose manufacturers strive to meet the rigorous standards of various industries, from automotive to construction, the integration of advanced materials becomes crucial. Reports indicate that hoses made from high-grade materials can outperform their counterparts by up to 50% in terms of lifespan and reliability, making the initial investment in quality a strategic move for manufacturers.

In the competitive landscape of hose manufacturing, the selection of quality materials stands at the forefront of ensuring performance and durability. The Global Hose Market, which is projected to reach USD 13 billion by 2026, emphasizes the growing importance of material quality in the production process. As hose manufacturers strive to meet the rigorous standards of various industries, from automotive to construction, the integration of advanced materials becomes crucial. Reports indicate that hoses made from high-grade materials can outperform their counterparts by up to 50% in terms of lifespan and reliability, making the initial investment in quality a strategic move for manufacturers.

In light of these findings, the need for hose manufacturers to focus on material selection cannot be overstated. According to a recent study by Smithers Pira, more than 60% of hose failures can be attributed to inferior material quality. Given the potential consequences of such failures, including safety hazards and increased operational costs, it is essential for manufacturers to prioritize sourcing and utilizing superior materials. This emphasis not only enhances the longevity of hoses but also elevates the overall market reputation of hose manufacturers, positioning them as leaders in innovation and quality assurance. Thus, understanding the intricate relationship between materials and performance is vital for any hose manufacturer aiming to thrive in a demanding market.

Understanding the Significance of Raw Materials in Hose Production

The significance of raw materials in hose production cannot be overstated. Quality materials directly affect not only the performance of hoses but also their durability and longevity. For instance, using high-grade rubber can enhance elasticity and resistance to environmental factors, which is essential in various applications, from industrial use to everyday household tasks. Recent market trends indicate that the Asia Pacific rubber hose market is poised for substantial growth, reflecting an increasing awareness of the importance of material quality in hose manufacturing.

Tips: When selecting materials for hose production, consider factors such as strength, flexibility, and resistance to chemicals. Ensure to source from reputable suppliers who provide detailed information about their raw materials.

Furthermore, the diversity in material types, such as stainless steel and plastic for hose clamps, illustrates the importance of pairing the right materials with specific applications. This attention to material selection not only improves functionality but also caters to the evolving demands of consumers. As markets continue to expand, understanding these nuances in hose production will be essential for manufacturers aiming to meet quality standards and performance expectations.

Tips: Regularly evaluate new material innovations to remain competitive. Staying updated with market trends can provide insights into emerging materials that enhance product performance.

Key Properties of Different Materials Used in Hose Manufacturing

When it comes to hose manufacturing, the choice of materials plays a pivotal role in determining both performance and durability. Materials such as rubber, PVC, polyurethane, and stainless steel are commonly used, each offering distinct properties that cater to specific applications. According to a report by the Rubber Manufacturers Association, hoses made from high-quality rubber can withstand extreme temperatures and have a resistance to ozone degradation, making them ideal for automotive and industrial applications.

PVC hoses, on the other hand, are known for their lightweight and flexible characteristics. The American Society for Testing and Materials (ASTM) highlights that PVC can maintain its dimensional stability under varying pressure conditions, which is crucial for water and chemical transfer applications. Meanwhile, polyurethane hoses are celebrated for their abrasion resistance and tensile strength, making them suitable for high-wear environments. The Hose Manufacturers Association notes that a polyurethane hose can outperform rubber in terms of fatigue life, often lasting up to 10 times longer under rigorous conditions.

Stainless steel is another noteworthy material, especially for high-pressure applications where corrosion resistance is vital. A study by the International Journal of Advanced Manufacturing Technology indicates that stainless steel hoses can maintain structural integrity under high temperatures and aggressive chemical exposure, making them an essential choice in industries such as pharmaceuticals and food processing. Each material's unique properties not only enhance hose performance but also contribute to better safety and reliability across various industrial sectors.

Unlocking the Secrets of Hose Manufacturing: How Quality Materials Enhance Performance and Durability

| Material Type | Key Properties | Applications | Durability Rating |

|---|---|---|---|

| Rubber | Flexible, high elasticity, weather-resistant | Industrial machinery, pneumatic systems | High |

| PVC | Lightweight, corrosion-resistant, low cost | Agricultural applications, low-pressure systems | Moderate |

| Nylon | High tensile strength, chemical resistance | Automotive, fuel delivery | Very High |

| Polyurethane | Abrasion-resistant, high flexibility | Food processing, medical applications | High |

| Silicone | Temperature resistance, non-toxic | Pharmaceuticals, food-grade applications | Very High |

Innovative Technologies Enhancing Hose Performance and Longevity

Innovative technologies are revolutionizing hose performance and longevity, a crucial aspect of various industries including automotive, agriculture, and manufacturing. Recent findings highlight the integral role of advanced materials in enhancing durability. For instance, studies indicate that per- and polyfluoroalkyl substances (PFAS) significantly improve the performance characteristics of hoses, offering resistance to heat and chemical exposure. This innovation aligns with industry trends that emphasize the importance of high-performance materials, particularly as the global radiator hose market anticipates robust growth through 2032.

Moreover, the introduction of PTFE composites has emerged as a game-changer in the aerospace sector, contributing to fuel efficiency and the extended lifespan of aircraft components. These advancements not only underscore the emphasis on material quality but also reflect growing industry demand for hoses that can withstand extreme conditions while maintaining operational efficiency. The latest hose designs, incorporating features like kink-free technology and high-pressure resistance, set new standards that further enhance user experience and functionality.

As industries continue to seek improvements, the integration of innovative materials will be key in driving future developments in hose manufacturing.

Factors Influencing the Selection of Hose Materials for Specific Applications

Selecting the right materials for hose manufacturing is pivotal to achieving optimal performance and durability in various applications. Each application has specific requirements, such as temperature tolerance, pressure resistance, or chemical compatibility, influencing the decision-making process. For instance, in medical device manufacturing, the evolution of thermoplastic polyurethanes (TPUs) has enhanced the capabilities of medical-grade tubing, offering greater flexibility and performance for sensitive applications. This innovation exemplifies how material advancements directly impact the functioning of hoses within specialized sectors.

Furthermore, the growing demand for fluoropolymer tubing illustrates the importance of material selection to address unique industry needs. Fluoropolymers like PTFE and FEP are renowned for their exceptional chemical resistance and stability at high temperatures, making them ideal for applications in power plants or industrial piping systems. Adhering to standards like ASME B31.3 ensures that the selected hose materials not only meet safety and performance guidelines but also enhance the overall efficiency and reliability of the systems they are integrated into. The intricate relationship between material properties and application demands underscores the vital role that informed material selection plays in the hose manufacturing industry.

The Role of Quality Control in Ensuring Hose Durability and Reliability

Quality control plays a pivotal role in ensuring the durability and reliability of hoses, significantly influencing their performance across various applications. According to a report by the International Rubber Study Group, hoses manufactured with stringent quality control processes can reduce failure rates by up to 30%, effectively enhancing safety and operational efficiency. This is particularly crucial in industries such as automotive and aerospace, where reliable performance is non-negotiable. The implementation of advanced testing methods, such as hydraulic testing and ozone resistance assessments, ensures that every hose meets or exceeds industry standards before reaching the market.

Furthermore, data from the Rubber Manufacturers Association indicates that approximately 25% of hose failures are attributed to material defects and manufacturing inconsistencies. By prioritizing quality control throughout the manufacturing process—beginning with the selection of high-grade materials to conducting thorough inspections—manufacturers can create hoses that not only perform better but also last considerably longer. The result is a marked decrease in downtime and maintenance costs, proving that a commitment to quality is essential for sustained operational success.

Related Posts

-

Understanding the Advantages of Fire Hose Garden Hose Combinations for Efficient Watering Techniques

-

The Ultimate Guide to Choosing the Right Marine Hose for Your Boat

-

The Ultimate Guide to Choosing the Right Flexible Gas Hose for Your Needs

-

Exploring the Evolution of Garden Hoses: Innovations Driving Water Efficiency in 2023

-

Unleashing the Power of Heavy Duty Hose for Industrial Applications and Beyond

-

Understanding the Essential Role of Industrial Hose Manufacturers in Modern Industries